|

Precision Engineering Services

At AGV

Precision, we offer you an extensive range of manufacturing services. We work to ISO 9000:2008. This

enhances quality and traceability.

We bridge the gap for companies, by providing a service for those how do not wish to invest in Machinery,

or whose job quantities do not validate the capital lay out.

AGV Precision is a jobbing shop that utilises state-of-the-art machinery to meet our clients' Tool Making,

Prototypes and High Precision engineering requirements.

|

Listed below are just some of the services

that we offer:-

- Wire Erosion (600mm x 400mm x 350mm)

- Profile Digitizing

- CNC Turning

- NC Milling and CNC Milling

- Surface and Universal Grinding

- Welding

- 3D Inspection

- Hard Turning / Milling

- Reverse Enginering

- Small batch work

|

Gear cutting

|

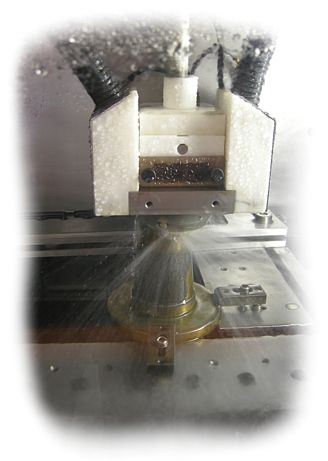

Wire Erosion

The wire

erosion process can be used to cut a wide range of materials, these

materials include – Stainless, Titanium, Cast alloy,

Tungsten Carbide, Aluminium Alloys, Graphite

and Copper.

High Precision wire erosion is done with Charmilles Technology EDM. We have the latest software which enables us to programme complicated 4 Axis programmes.

|

Wire Erosion in progress

|

Special Features...

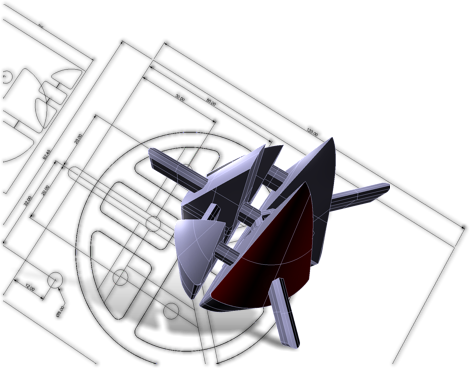

Reverse Engineering:

For 2D scanning we use the Renishaw Scanner, and the 7 Axis Romer Absolute Laser Scanner for 3D scanning and inspection reports, and for comparing scanned modules with CAD modules.

|

| |

Our Services...

- Jigs and fixtures

- Tools, and refurbishment of tools

- Dies & Punches

- High Precision small Gears

- Precision Components

- Gauges with test certificates

- Precision Medical Equipment

- Spark Erosion

- Digitizing

- Universal Grinding

|

|

|

|

|

|